Using the PSM as an Autocollimator

The other day I got a call from a PSM user asking about calibration. What he was really asking about was the setting of the zero, or origin, on the video screen.

CROSSHAIRS IN THE CENTER OF THE FIELD

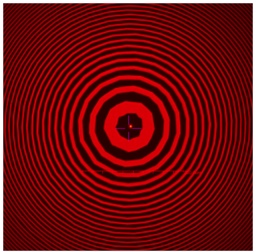

This is the same sort of “calibration” people talk about when using autocollimators, which are the crosshairs in the center of the field. Here you can use a corner reflector or rotate the collimator in its mount to see if the target appears to move. If the target moves as the autocollimator is rotated about its axis, the crosshairs are not centered. (For more on autocollimators, see below.)

EQUIVALENT CALIBRATION

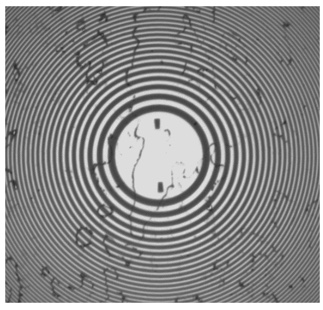

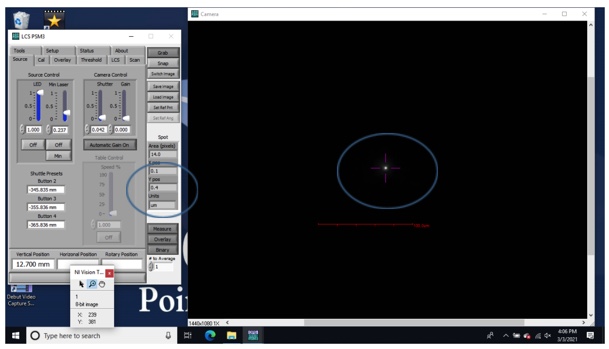

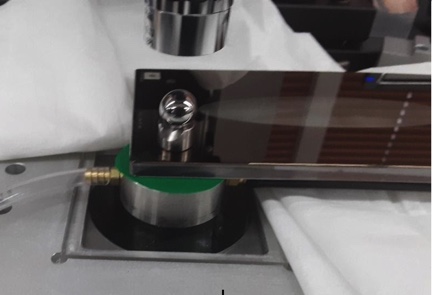

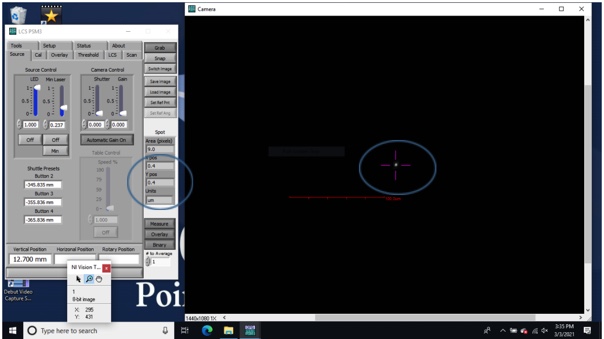

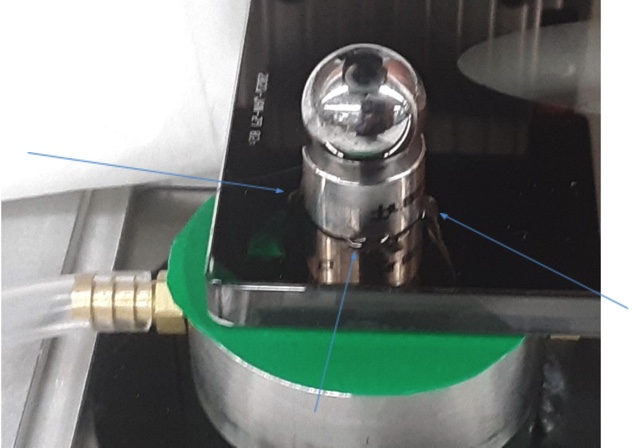

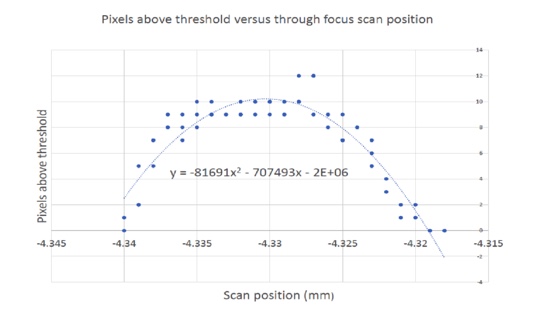

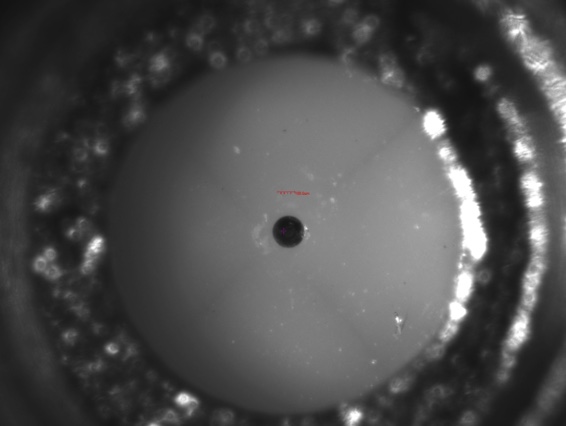

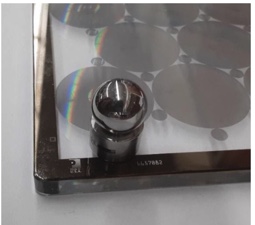

The equivalent calibration for the PSM is to focus on a specular surface to get a well-focused return spot, a Cat’s eye reflection, and click the Set Ref Pnt button to center the crosshairs on the return spot electronically. This operation is the equivalent of bore sighting a rifle scope. When the crosshair is centered on the Cat’s eye reflection the focus of the PSM objective is centered in the crosshair.

Thus, when a return reflection is also centered in the crosshair, the return reflection is coincident with the outgoing light focus. In this way you can be sure you are at the center of curvature of a concave mirror to better than 1 μm when the PSM is used with a 10x objective, the standard sold with the PSM. Obviously, a higher resolution is achieved with a higher power objective.

THE CALIBRATION FACTOR

If by calibration you mean when the PSM says the return spot is 54.2 μm from the crosshair, is it really 54.2 μm or is it 54.4 μm?

For most users, simply setting the Calibration Factor to 1.00 when using the standard 10x objective is good enough. For those who want to know the distance to the last μm the answer is to use a calibrated line width standard and measure it to see if the value you get with the PSM is the same as the standard. If it is not, the Calibration Factor can be tweaked to give a precise reading.

When using an objective other than the 10x Nikon objective supplied with the PSM you may want to change the Calibration Factor to get the correct reading in μms. For those not having a suitable line width standard, we have standards traceable to NIST for sale in our webstore.

THE PSM ALSO WORKS AS AN AUTOCOLLIMATOR

Recently we have sold several PSMs to a customer that wanted the PSM strictly as an autocollimator.

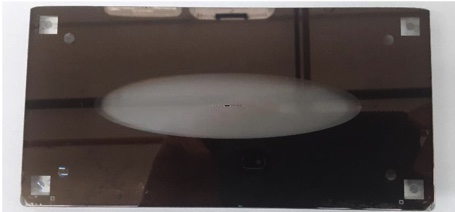

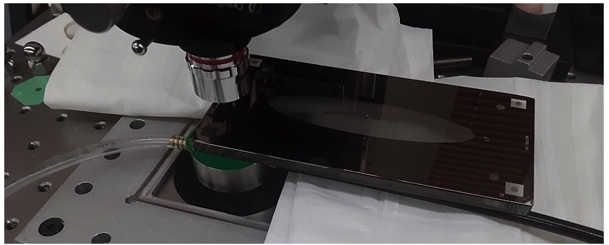

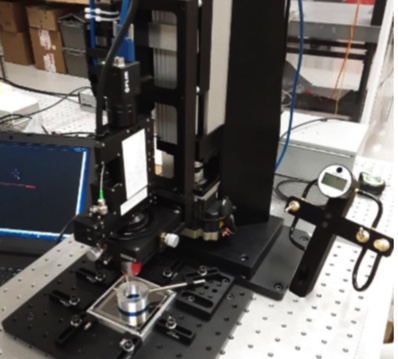

They wanted to build the PSM autocollimators into their hardware as permanent measurement devices and did not have space or stiffness to support a standard autocollimator that tends to be 500 mm or so long and weighs several kilograms.

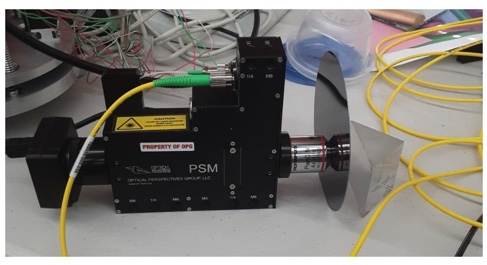

As you may (or may not) know, the PSM works as an autocollimator by simply removing the objective and it has a resolution of better than 1 arc second.

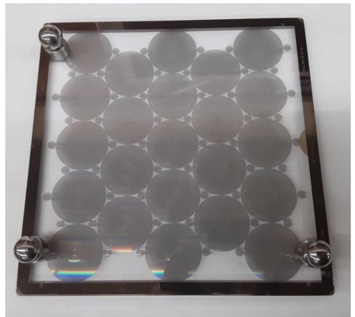

For this particular customer, the PSM was a perfect solution since the PSM is about the size of your hand and weighs about half a kilogram. Another advantage for this customer was that their target was rather small, less than 10 mm in diameter. This fit nicely with the PSM collimated beam output diameter of 6 mm, much better than a standard autocollimator with a beam diameter of over 25 mm where most of the light falls off the target or is reflected as scattered light.

MACHINE VISION AUTOMATION SCHEME FOR LIMITED SPACE

I am publishing this article, because I got the call from someone who wanted a PSM as an autocollimator for just this reason, to incorporate in a machine vision, automation scheme with limited space.

This got me thinking that we have always stressed using the PSM for alignment and centering and have treated its use as an autocollimator as a very secondary use.

The call from the customer who wanted to use the PSM for an autocollimator, made me realize that there is a customer base who really needs a compact, electronic autocollimator. The PSM may be just what they are looking for.