Systematic method of alignment using aberrations

ABSTRACT: Talk is largely tutorial by has a two-fold motivation Definitions of kinds of alignment

Initial alignment steps to get light into alignment sensor-autostigmatic microscope, alignment telescope or interferometer Systematic alignment steps using the alignment sensor. Good idea to have a written procedure because many steps Alignment results using real hardware.

Robert E. Parks, Benjamin F. Anjakos

Optical Perspectives Group, LLC Tucson, AZ 85750

Steward Observatory, Univ. of Arizona Tucson, AZ 85721

Optomechanical Engineering 2023 SPIE Optics and Photonics

20-25 August 2023

Background and motivation

- Work on a project where alignment was critical

- Discussions with optical engineers without much hands-onexperience in alignment, had little idea of how well they couldposition hardware – saw need for a procedure

- Connection between image symmetry and kinematics of alignment

- Writing a blog on alignment that might become a book

- Awareness of new software to make alignment more quantitative

(My) definitions of alignment

Hard alignment – uses centers of curvature, reticles at vertices and foci

Reflected centroid identified to the ± 1 μm level in 3 degrees of freedom (DOF)

Soft alignment – centering the test wavefront on the aperture of the article under test Usually fine if centered to a couple of degrees, often eyeball is good enough

Alignment with aberrations – centers of curvature and vertices difficult/impossible to reach optically

Forced to rely on aberrations for alignment

3 degrees of freedom (DOF)

5 DOF – 3 at focus, 2 at flat

Initial steps to get light into alignment sensor

- Set the x-y axis origin of the sensor using a Cat’s eye reflection

- Provide mounts with sufficient range of motion and DOF for alignment

- Position mounts with elements as close as possible mechanically

- Use a low power objective or reduce aperture of transmission sphere initially

- Adjust point source of light to produce expected behavior on first reflection

- Adjust return mirror to center reflected beam on sensor aperture

- Adjust return beam focus to outgoing focus

- Perform systematic alignment using quantitative feedback from sensor

Set x-y axis origin in sensor

To eliminate retrace error the reflected path must overlay the outgoing path

This is effectively boresighting the alignment sensor

Use a Cat’s eye reflection from a specular surface at the focus of the sensor Interferometers have built in functions to help with this, rotation serves this purpose with

alignment telescopes and autostigmatic microscopes centroid electronically

Tilt fringes in an interferometer are the analog of an image being decentered in an AT or ASM

Mounts for optical elements

Mounts must have the necessary DOF to achieve alignment, but no more than necessary

Too many adjustments make alignment confusing

Mounts need the necessary range of travel but be sensitive to adjustment at alignment level May need actuators if touching by hand introduces unacceptable errors

Adjust mounts to mid-travel range, if possible, before screwing to table

Mounts must be stable, screwed to table – stacks must be kinematically secure Use spacers at 3 points to assure kinematic stability

Locate mounts precisely mechanically

If possible, make optical axis of the alignment setup parallel to table top

The centers of all apertures are the same height to 1 mm or less

As the axis height reference, use the component with the least flexibility to adjust

An interferometer would be a good example of inflexibility Use the tapped holes as a guide in the plane of the table

Use a plastic ruler to help position mounts

Don’t be afraid to use a Sharpie to mark locations – it wipes off with alcohol Add mounts one at a time starting at the source to get optical path started correctly

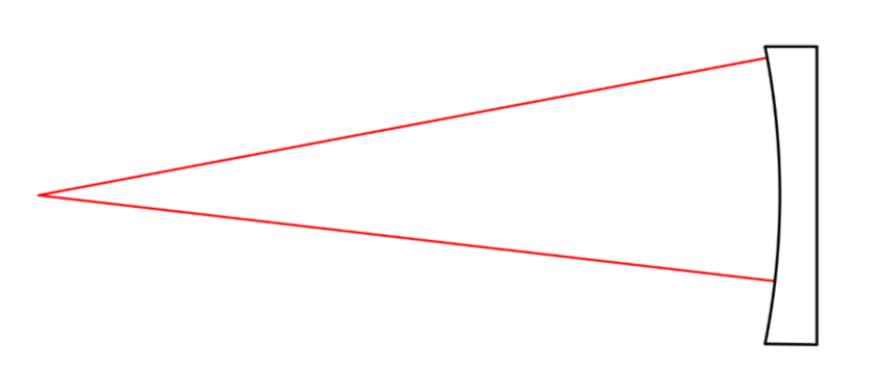

Alignment is paraxial – use low NA beam initially

Just as when using a microscope, start with the least powerful objective

Find area of interest, and switch to higher power while keeping object centered

Easy to start with a low power objective with an ASM because objectives are parfocal Transmission sphere are not parfocal, use one that overfills the aperture Lower the NA by masking the transmission sphere

Once alignment is reasonably good, change objectives and remove mask to fill aperture Using aberrations forces the use of the full aperture

Keep components as close together as possible

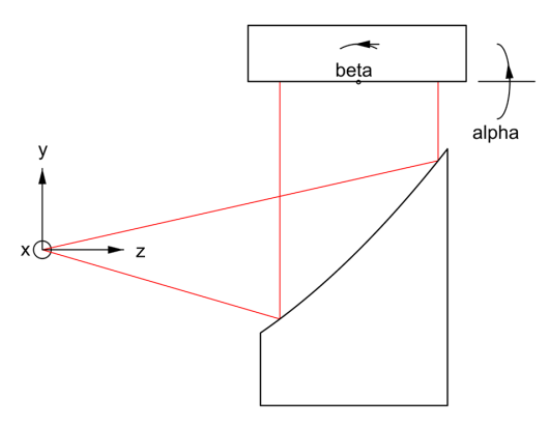

As in the picture keep the flat close, initially

This reduces the beam translation due to small angular errors in alignment

Once source and parabola well aligned, flat can be moved away because alignment is fixed

If return mirror has power, it must be located at the proper spacing

Using the low power objective or stopped aperture helps in this case

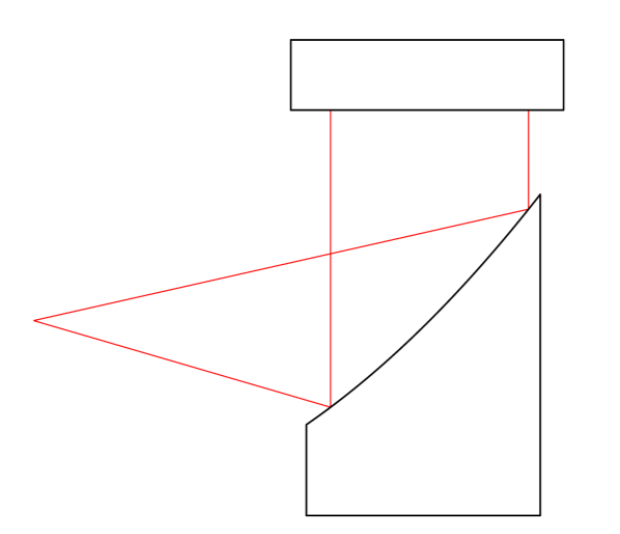

Adjust source relative to the first surface

Before adding the flat, look at the reflected beam for collimation and symmetry Use a bright source and white card to view the reflected beam

Since it is a parabola, the beam should remain reasonably well collimated

If not, adjust source distance from parabola until it is Reflected beam cross section should be round moving away from the parabola

If not, move the source in x-y to improve roundness

Adjust the return mirror to follow the beam back to source

With the return mirror in place, adjust it in tip/tilt to make the reflected beam follow the outgoing Probe the edges of the beam and tilt the mirror to overlap the 2 beams

If the alignment is anywhere close the reflected image should be near the outgoing focused spot Leave a little lateral misalignment to find the return image

Adjust focus of return spot to the same plane as the outgoing spot

Finally, overlap the images and the return image should be visible in the alignment sensor

Adjust the return mirror to center image

This is the beginning of the quantitative alignment

First adjust the return mirror, or the alignment sensor to center the spot on the crosshair Adjust focus to what appears best focus and adjust camera gain to 1/3 total range

Want to avoid saturated pixels at best focus when well aligned

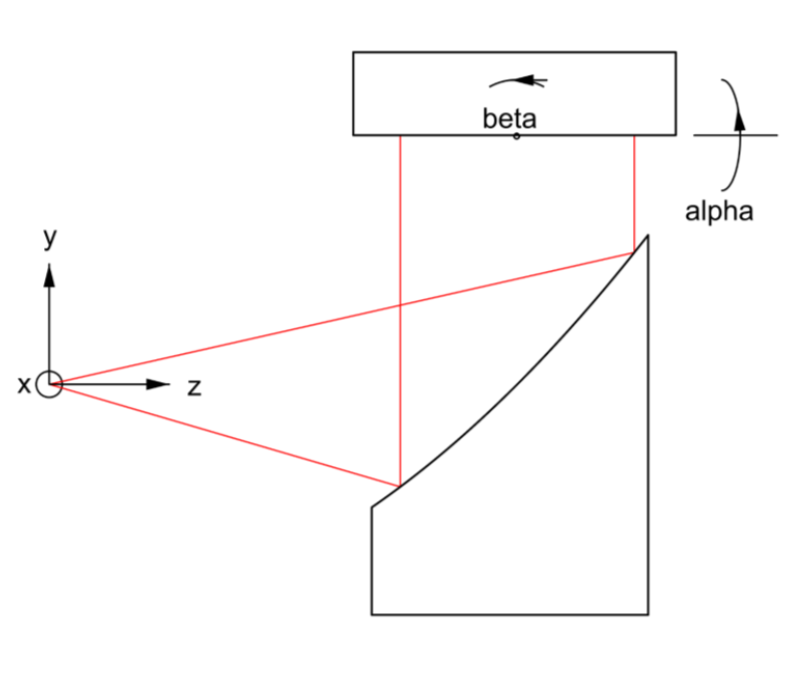

Alignment methodology

Must keep image centered on crosshair to avoid retrace error

Means making compensating tilt and decenter adjustments to reduce image size Along with keeping sensor adjusted for best focus

With the 90° parabola the main aberration is astigmatism First alignment step is to check for best focus Astigmatism rotates 90° on either side of best focus Check sign or orientation of astigmatism with focus

Good idea to have written procedure and to make notes Next chart shows alignment steps

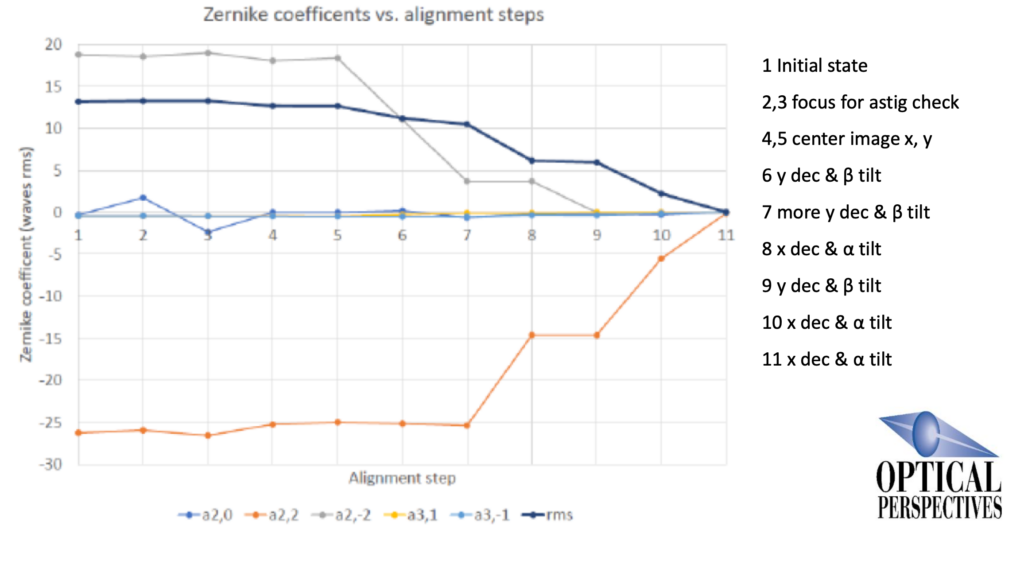

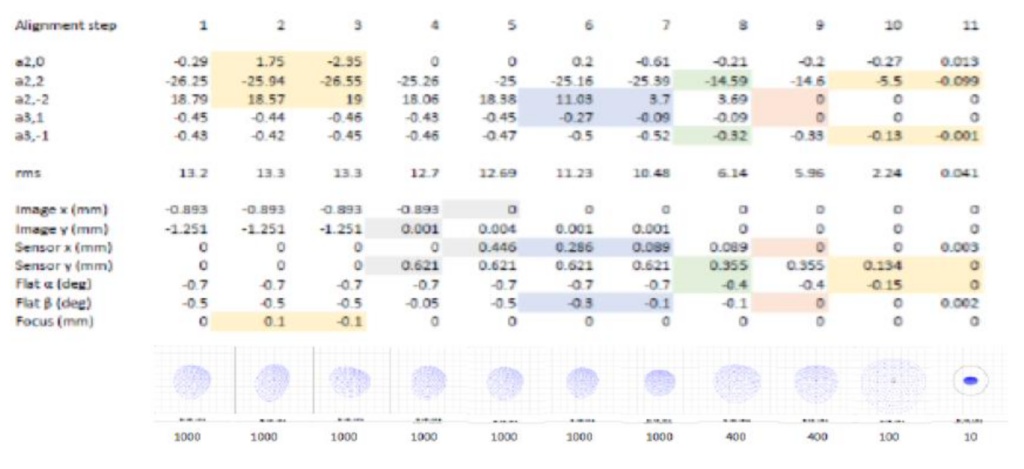

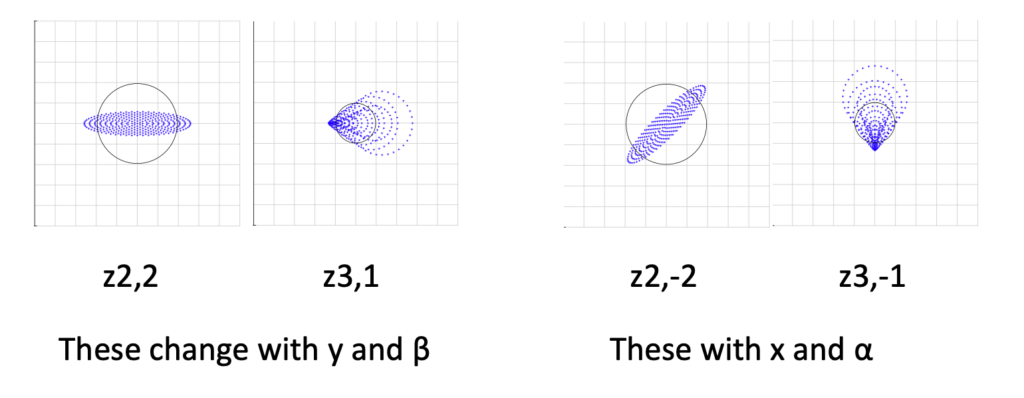

Change in Zernike coefficient with alignment step

Change in alignment and image with each step

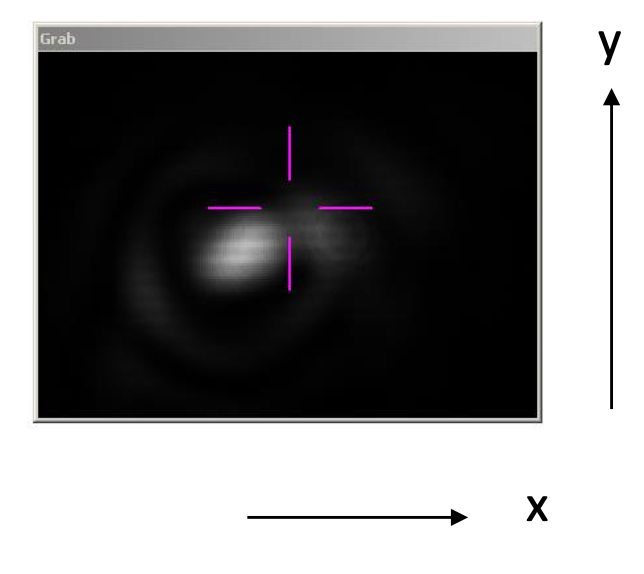

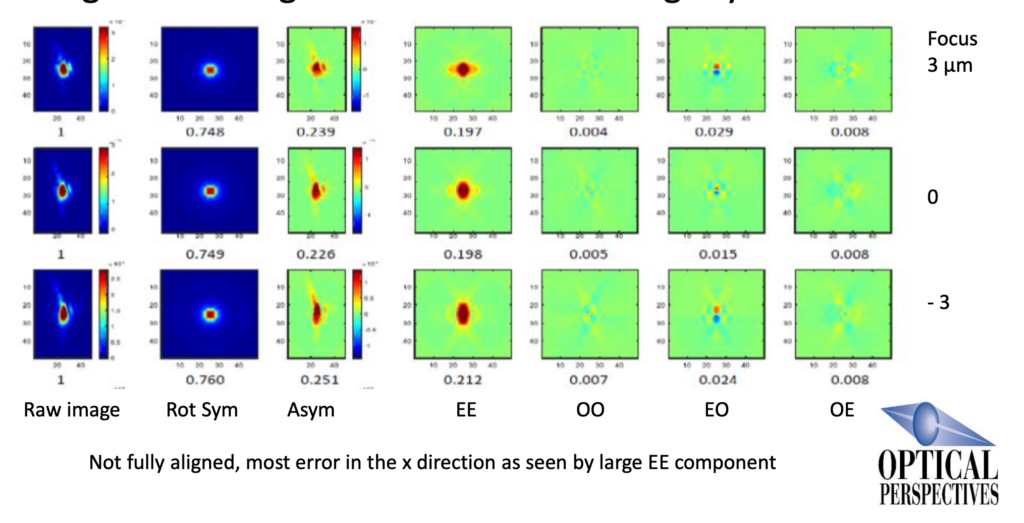

Alignment using real hardware and image symmetries

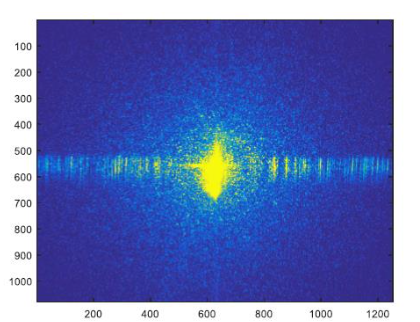

Concluding observations about the images

Obviously diamond turned surface – horizontal diffraction patten (Oversaturated to show diffraction)

Irregularly shaped image indicates mid-spatial frequency errors

Conclusions about alignment with aberrations

Showed some simple methods of making initial alignment easier

Showed making compensating adjustments keeping image centered

Showed how 5 adjustments match 1:1 with 5 image symmetries

Showed how image symmetries guide which adjustment

Showed sensitivity of image characteristics to alignment

References

Parks, R. “Using image symmetries to uniquely align aspheric mirrors to a focus and axis”, Proc. SPIE, 12222, pp. 24-32 (2022).