Reverse Engineering Lens Elements

Introduction

- Need for reverse engineering

- Properties necessary for reverse engineering

- How to make necessary measurements

- How to calculate the paraxial properties

- Use of a spreadsheet for the solution

- Use of a lens design program to find a solution

Need for reverse engineering

- Actually want to copy someone’s design

- Concern that lens may be wrong glass

- Lenses got mixed up, need to sort out

- Lens system does not work – right elements?

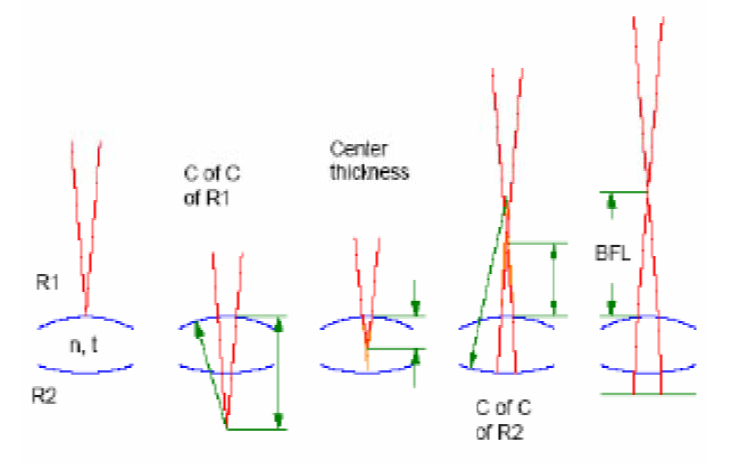

Properties needed to reverse engineer

- Just looking for paraxial properties

- These are the properties on an optical drawing

- Two radii

- Glass type or index at the measurement wavelength

- Center thickness

- Could measure physically, but may not want to, or can’t

Measurements needed

- Radius of curvature but may not have working distance – reverse lens so backside concave

- Optical center thickness to rear vertex

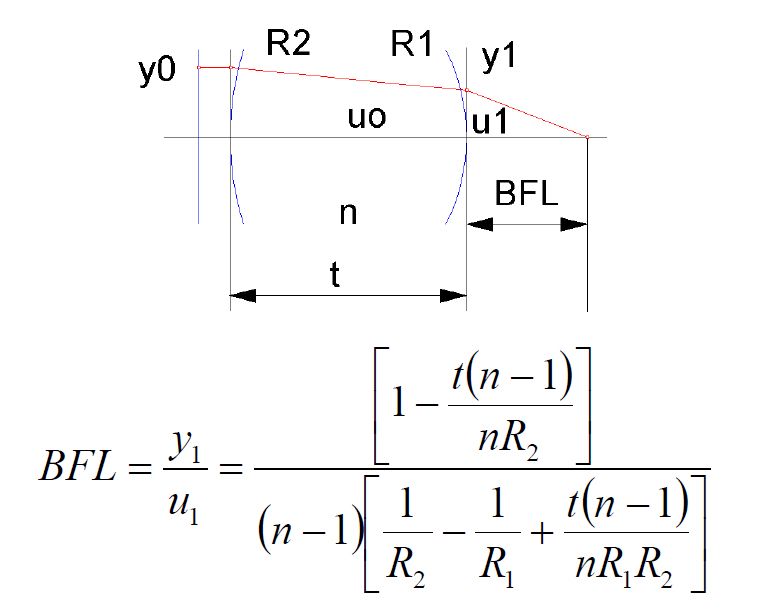

- Back focal length from one or both sides

- Need at least 4 measurements to solve for 4

unknowns - Extra measurements increase confidence

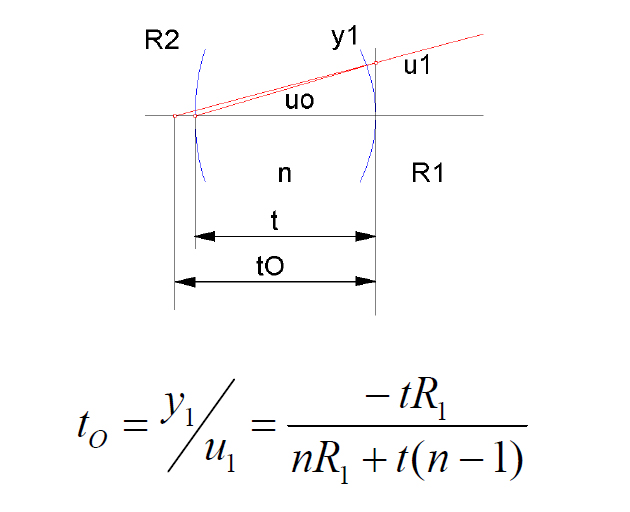

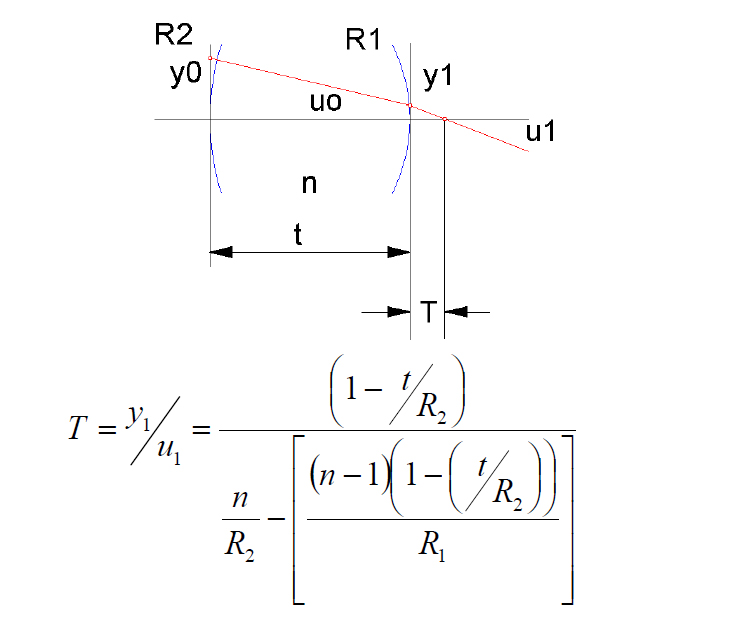

Measurements that can be made

Center thickness

Rear Radius

Back focal length

No closed form solution for unknowns

- Use spreadsheet

- Find difference between measured & guessed values

- Square differences and sum

- Make sum zero by varying unknowns

- Use a lens design program

- Model the various measurement configurations

- Use multi-configuration option

- Use plane surfaces, guess thickness and a model for index

- Use optimizer to find solution

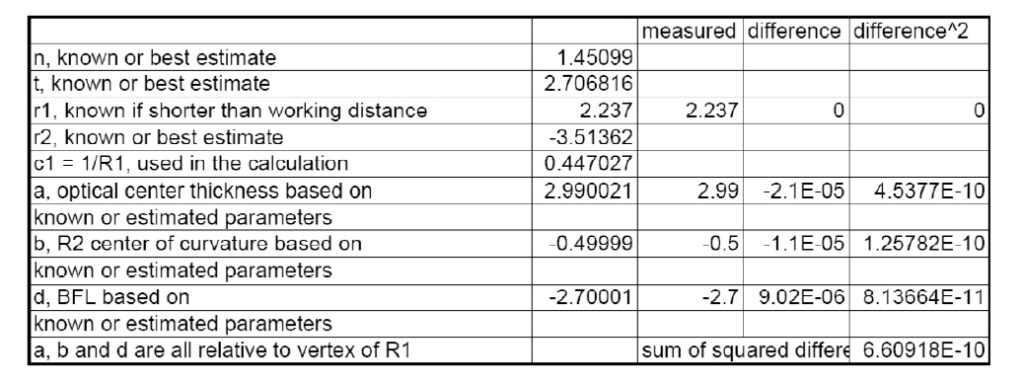

Spreadsheet example

N, t and r2 were estimated and a, b and c calculated

Solver used to minimize lower right hand cell to give calculated n, t and r2 shown above.

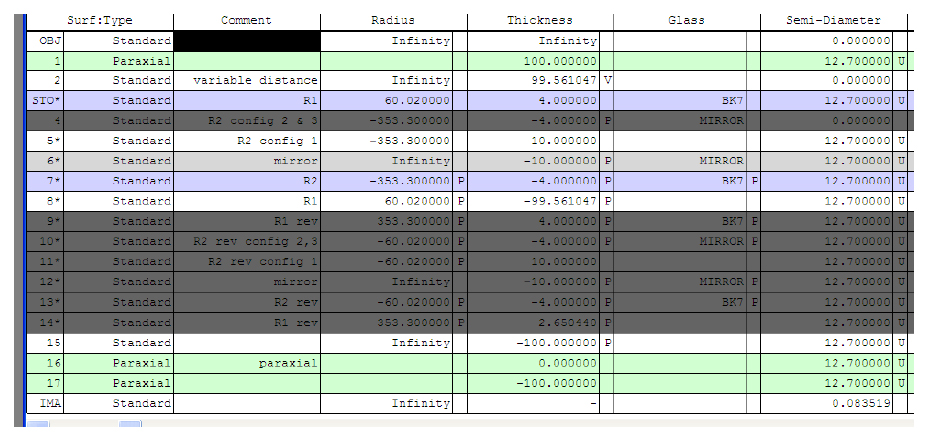

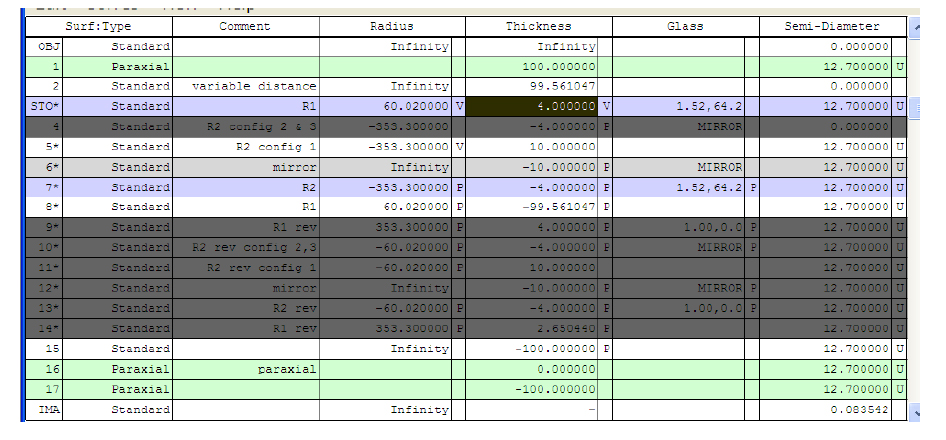

Lens design example

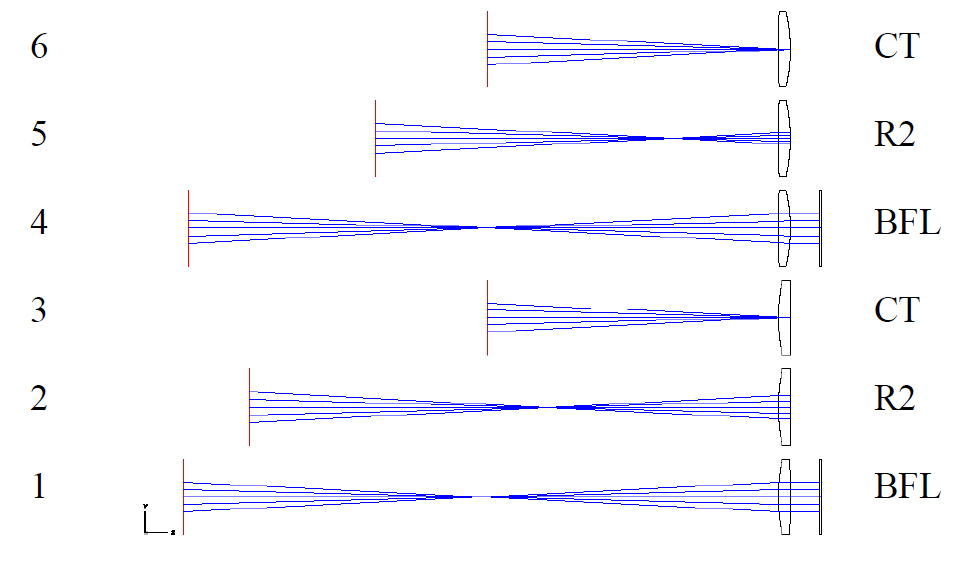

Configuration 1 shown for calculation of bfl

Grayed out lines are ignored

Lens design example con’t 1

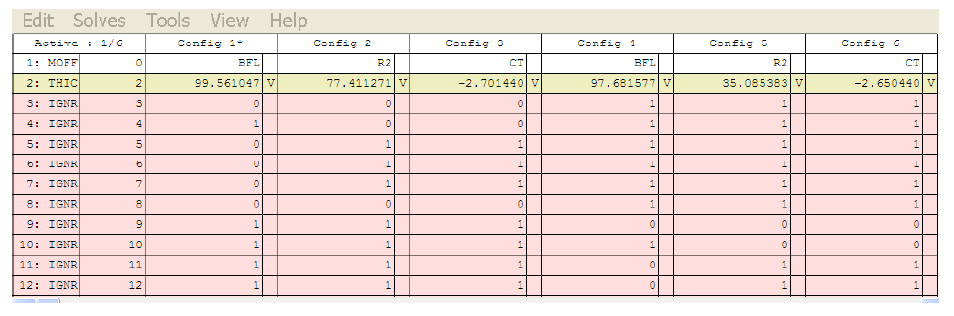

Configurations 1, 2 and 3 are looking thru short radius first

Configurations 4,5 and 6 are looking thru long radius first

Line 2 shows what the measurements should be knowing the index, thickness and two radii

Lens design example con’t 2

Lens design example con’t 3

Radii, thickness and index are set as variables

Optimized with small entrance pupil for paraxial solution

Conclusions

- Use all practical conjugate measurements in model

- Works with interferometer or autostigmatic microscope

- Works for doublets as well as singlets

- Can usually see cement interface

- Often better reflection than AR coated surfaces

- Just a more complicated lens design model

- Need to know surfaces from centers of curvature

- Remember to stop down model before optimization

- Model must find first order solution

- All in all, pretty easy to do